Multi Function Separator: Metal + Color / CSP – Separator

|

SpekMAG HR

|

Application of SpekMAG HR:

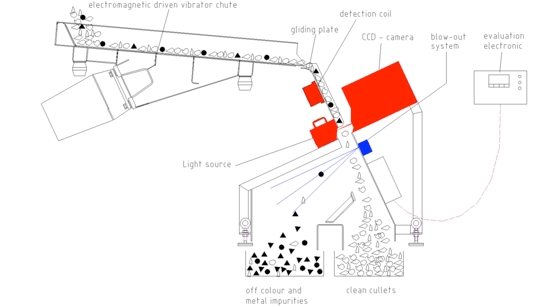

The true color + metal separator SpekMAG is a combination of Spektrum and MAG. The SpekMAG is able to eject off colors and / or CSP (Ceramic, Stones, Porcelain) and metals (ferrous and non ferrous) out of cullet. It is used for applications where highest throughput capacities and lowest off-color- / CSP and metal content in the end product is required. The SpekMAG consists of a light source, a high speed CCD-line-camera, a multi segment metal detection coil, an evaluation electronic and an air ejection unit.

Typical applications of the SpekMAG separators are the ejection from:

- Metals + Amber glass from a mixed stream

- Metals + Flint glass from a mixed stream

- Metals + Green glass from a mixed stream

- Mixed glass can be separated into flint, green and amber cullet in combination with metal separation

(several stages are required) - Metals + CSP (Ceramic, Stones, Porcelain) and other non transparent impurities out of glass cullet

Requirements:

- The cullet must be divided into different fractions

- Coarse ferrous metals should be separated by magnets

- Coarse waste rejected

- Light weight impurities like aluminum foil, paper etc. should be rejected

- Vibration free installation + in-house mounting

- Feeding by means of an electromagnetic driven vibrator chute (speed > 0,3m/s)

- Cullet should be evenly distributed over the working width of the separator

- Compressed air must be free of dust, water and oil

Please give us some details of your application – It would be our pleasure to help you