All Metal Separator

|

|

MAG 4400

|

Application of MAG 4400:

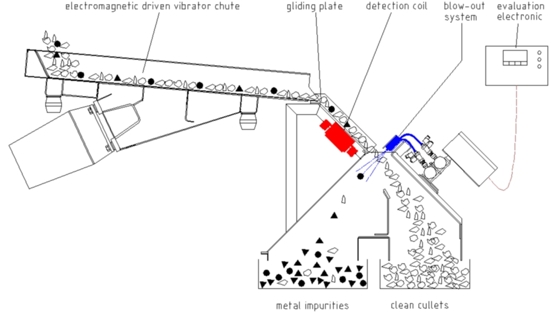

The all metal separator MAG 4400 automatically removes any ferrous & non-ferrous metals out of cullet. The MAG is used for applications where highest throughput capacities and lowest metal impurities in the end product are required. The MAG 4400 consists of a multi segment metal detection coil, an evaluation electronic and an air ejection unit.

A typical application of the MAG 4400 is the ejection of:

- Aluminum foils, aluminum caps, aluminum rings and segments of rings

- Lead and other non ferrous metals like copper, brass, stainless steel,…

- Ferrous metals

- Wired glass

- Fine pieces of metal

- Metals sticking in glass

- Metals enclosed in rubber or cullet

Requirements:

- Coarse ferrous metals should be separated by magnets

- Coarse waste should be sorted out manually

- Light weight impurities, such as paper, aluminum foil, a.s.o. should be separated

- Vibration free installation + in-house mounting

- Feeding by means of an electromagnetic driven vibrator chute (speed > 0,3m/s)

- Cullet should be evenly distributed over the working width of the separator

- Compressed air must be free of dust, water and oil

Please give us some details of your application – It would be our pleasure to help you